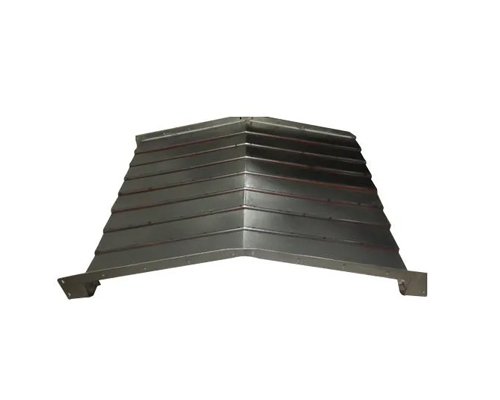

Telescopic Covers Dealers in Sriperumbudur, Tiruvallur

Telescopic Covers Dealers in Sriperumbudur,Tiruvallur – Engineering Access is gives you genuine and verified suppliers of Telescope Cover in Tiruvallur.

Telescopic Covers Dealers in Sriperumbudur,Tiruvallur – Engineering Access is considered a renowned name in the field that manufactures and supplies Telescopic Covers, which reduce sideways wearing, thus maintaining the accuracy of the machines. The planned selection is extremely popular for protecting columns, spindles, ball screws, and shaft, by avoiding the accidental risk.

Engineering Access is Manufacturer and dealer of Telescopic Covers, CNC Machines Telescopic Covers, SS (Stainless Steel) Telescopic Covers and Industrial Telescopic Covers from Sriperumbudur,Tiruvallur .

We have developed an advanced infrastructural facility that is spread across the vast area of the land. This is segmented into various units like manufacturing, quality testing, warehousing and packaging and after sale support. All our infrastructural units help us in meeting the bulk and immediate demands of our clients within predefined time schedules.

Give us a call! We’re here for you. +91 98841 25906

For any further information about equipments, email us at engineeringaccess2019@gmail.com

Automatic Lubrication Pumping Solutions in Chennai

We are involved in wide spectrum of activities such as manufacturing, import, export, trading & providing technical assistance through Consulting & project Management to our clients in oil & gas, civil, mechanical, electro mechanical construction, flood controlling, drainage cleaning, soil excavation, mining & piling sectors.

Our expertise includes dewatering contracting services, equipment’s hire, pumping solution to the clients by offering centrifugal pumps, high head pumps, high pressure pumps, high discharge pumps, open well pumps, deep well pumps with utmost quality & sincerity.

Fluid Dispensing Equipment Sellers and Dealers in Chennai

An Engineering Access has been improved, upgraded and fine-tuned. It delivers even better dependability and productivity combined with minimal maintenance and process downtime, especially crucial in demanding applications such as the automotive or aerospace industry and their supply chains.

Designed compactly for maximum uptime with minimal moving parts and large clearance, the Engineering Access Lubrication pump has advanced balancing that reduces vibration and is easy to maintain. Add a booster to the Engineering Access to increase the pumping speed. Every feature works towards providing you with exactly what you need. From a low lifecycle cost, to in-house service for extra peace of mind, to reliable operation. Keeping in mind the automotive and aerospace industry and their supply chains, the Engineering Access has been improved, upgraded and fine-tuned.

Chennai’s Best Automatic lubrication system

Simplifying maintenance

Engineering Access offering a high range of Guide ways, racks, and pinions can be lubricated by an optional automatic lubrication system. Depending on customer needs and integration requirements, the selected system reduces the downtimes of the overall plant.

Engineering Access provides documents for installation, integration, and operation. Orientation aids for lubricants, lubrication interval, and cycle, or quantity, help to ensure an adequate lubricating film.

Engineering Access-Automatic Lubrication System

The Engineering Access automatic lubrication system is a lubrication system for Engineering Access components. The Engineering Access feeds the lubricant from the cartridge into the lines. Depending on the design, the lubricant is distributed through splitters, combined through Y-segments, or distributed directly to the lubrication areas. Rack and pinions are lubricated by lubricating pinions; guide ways are lubricated by lubricating elements.

We are backed by an advanced manufacturing unit, which is equipped with cutting-edge technology and modern machines, from where the products are rolled off standing high on precision and design. Also we ensure not to waver when it comes to offering the products with the guarantee of supreme quality. We have quality testing Rigs, where in we ascertain that the products meet all the applicable standards/norms so as to appease the buyers.

Why Choose Our Lubrication pumps?

- Lubrication systems improve the life time of your machines

- To lubricate each part of the bearing, and to reduce friction and wear

- To carry away heat generated inside bearing due to friction and other causes

- To cover rolling contact surface with the proper oil film in order to prolong bearing fatigue life.

- To prevent corrosion and contamination by dirt

It’s great to learn that our company offers a complete range of Centralized Lubrication System Spares, including high pressure grease pumps, motorized pumps, and control valves. As a manufacturer and supplier, you have demonstrated your capabilities to process both retail and bulk orders efficiently, which is essential in meeting the needs of your diverse customer base. Your ability to process orders even on short notice is sure to be appreciated by your clients, as it allows them to keep their operations running smoothly with minimum downtime. Keep up the good work in providing quality products and responsive service to your customers.

For visit us google maps